In our previous articles, we have explained you the Water Cycle of thermal power plant. This Water cycle consists of Feed Water Cycle and Condensate Water Cycle. Condensate water cycle is from Condenser to the Deaerator and feed water cycle is from Deaerator to the Boiler Drum. Impact of Dissolved gasses in Feed-water It is an utmost necessary […]

Category Archives: Turbine & Auxilaries

Want to know about the various processes involved while starting a unit? Then you are at the right place because we have stuffed all the details involved in the start-up of a Sub-critical Tangential Firing unit. Below we have explained the start-up procedure types and various processes involved in case of tangential fired sub-critical boiler […]

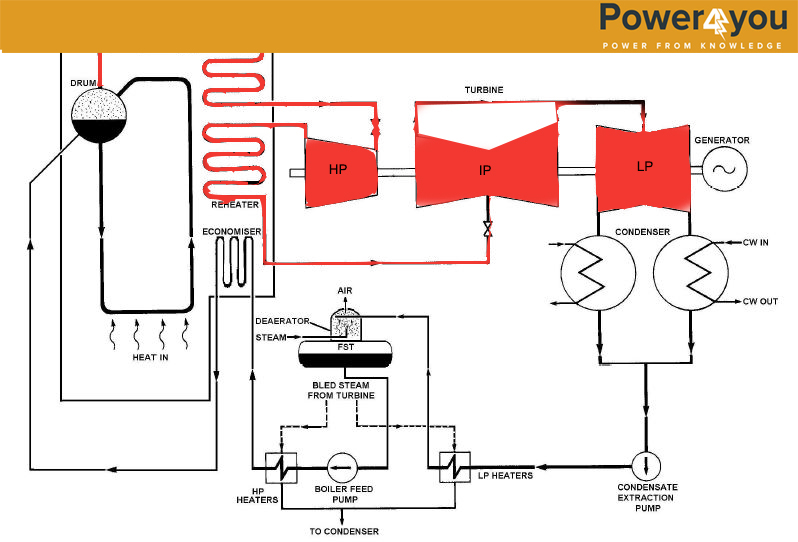

Thermal Power Plant is based on the Rankine cycle and in Ideal Rankine cycle, there are 4 processes and those are Heat Addition at Constant Pressure in Boiler, Isentropic Expansion in Turbine, Constant Pressure Heat Rejection in Condenser and Isentropic Compression in Pumps. So now we will discuss about the condenser, which plays a very […]

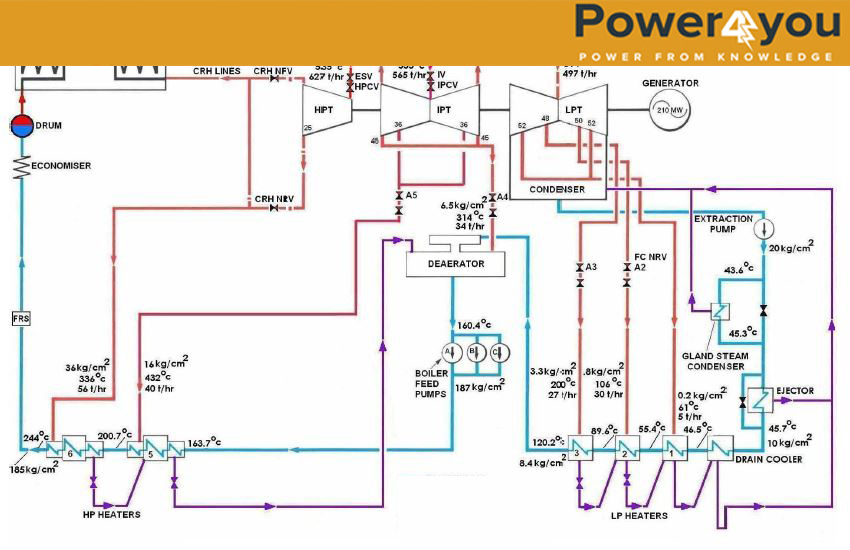

In any thermal power plant, there are mainly three cycles i.e. Steam Cycle, Condensate cycle and Feed water cycle. We have already discussed the steam cycle in thermal power plant and now we will discuss about the Condensate cycle & Feed-water cycle. These two cycles are very important in efficiency point of view. As we […]

In order to generate electricity, we require mechanical torque and for the mechanical torque we require a fluid which will rotate the turbine, in thermal power plants to rotate the turbine we use steam as a medium. Steam is generated in boiler with the help of coal and water and after burning the coal, the […]

The efficiency of a basic Rankin cycle is very less due to the enthalpy loss in the condenser. So the reheat and the regenerative cycle are used to increase the efficiency of the Rankin cycle.Here we will discuss how regenerative cycle is used in thermal power plant. (Rankin cycle with regenerative feed heating) If the […]

Based on the steam flow: Single-flow: the steam is admitted at the one end of the turbine in the first stage blades. Steam flows axially through the radially-mounted blades and exhausts at the other end after expansion (specific volume is increased). Double-flow: In this type of arrangement the steam is admitted at the center of […]

Efficiency Efficiency in turbine is defined as the ratio of the amount of work done by the turbine to the amount of heat transferred to the turbine by the working fluid and the efficiency at which the heat is transferred to the turbine rotating blades is dependent on the ratio of moving blade velocity and […]

Theory: The steam turbine is the most versatile prime mover, which is capable of almost endless applications. A machine, which originates mechanical motion by using some natural force, is called prime mover. Steam turbine is a practical power source and is built in as small size as 5 KW to as large as 1300 MW. […]